“NanoNC” aims to perfect the experiment.

Our products prioritize customer satisfaction and consistently yield

dependable experimental results.

eS-robot is easy to use with a user-friendly interface and easy-to-use approach, and offers exceptional performance and reliability that can be referenced in hundreds of papers.

*google scholar keyword: NanoNC, electrospinning, electrospray

Type 1.

ESR200 series

high scalability and customizability

Results manufactured in a 2D plane according to the movement of the robot

Touch screen

950(W) x 650~750(D) x 1,150(H) (mm)

30kV or 60kV (option: -30kV)

Type 2.

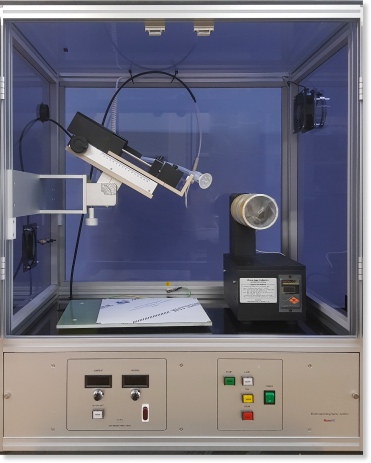

ESR100 series

both simple and reliable

Limited area manufactured at a fixed point

Result of uneven thickness

Individual button type

950(W) x 650~750(D) x 1,150(H) (mm)

30kV or 60kV (option: -30kV)

Syringe Volume : 1~200mL

Type 3.

RTR machine series

Expanding research scale

2D results made continuously for several meters with RTR construction

Touch screen

950~1,200(W) x 650~800(D) x 1,900(H) (mm)

30kV or 60kV or 100kV (option: -30kV)

Type 1.

ESR200 series

· The ideal choice for researchers due to its high scalability and customizability.

· Easy change to vertical and horizontal structures.

· User-friendly interface

Machine 1

: 1-axis robot with drum collector

Machine 2

: 2-axis robot with flat plate collector

Machine 3

: 2-axis robot with flat plate collector & drum collector

Machine 4

: 2-axis robot with vertical collector

Machine 5

: 2-axis robot with drum collector for 2-solutions

Machine 7

: desktop robot system with drum collector

Type 2.

ESR100 series

· Both simple and reliable.

· Easy change to vertical and horizontal structures.

· Individual button type

Machine 11

: not movement with flat plate collector

Machine 12

: not movement with drum collector

Machine 14

: traverse syringe pump

Machine 15

: 2-solution with drum collector

Machine 20

: nanofiber yarn system

Machine 21

: large discharge amount with air-jet blowing nozzle

Other Machine

: melt blowing system

Type 3.

RTR machine series

· Expanding research with “RTR machine series” to continuous production.

· Special nozzle for mass production, patented product of “NanoNC”.

· customizable to suit your needs.